Yes, a 1.5-inch pipe will significantly restrict more airflow than a 2-inch pipe at a flow rate of 300 CFM. Because air must travel through a smaller cross-sectional area, it must move much faster to maintain the same CFM. This increased velocity leads to a dramatic rise in friction loss and pressure drop. VMAC Air Compressors +3Performance Comparison for 300 CFM Air Velocity: For \(300\text{\ CFM}\), the velocity in a \(1.5\text{-inch}\) pipe is roughly \(24,000\text{\ FPM}\), while in a \(2\text{-inch}\) pipe, it drops to approximately \(13,750\text{\ FPM}\). High velocities (exceeding \(20\text{--}30\text{\ fps}\) or \(1,200\text{--}1,800\text{\ FPM}\)) are generally discouraged in main headers due to excessive energy loss.Pressure Drop: Resistance increases exponentially as diameter decreases. At this high flow rate, a \(1.5\text{-inch}\) pipe is typically considered undersized, often exceeding recommended flow capacities which can lead to a "choked" effect or overworked blower motors.Recommended Sizing: For \(300\text{\ CFM}\), experts typically recommend at least a \(2\text{-inch}\) or even a \(2.5\text{-inch}\) pipe to keep pressure losses manageable. Impact on Your Blower Backpressure: Using a \(1.5\text{-inch}\) pipe forces your blower to work against higher backpressure, which increases the heat generated and the Brake Horsepower (BHP) required from the motor.Efficiency: A \(2\text{-inch}\) pipe allows for smoother, more efficient air transport, reducing energy costs and potential vibration or noise issues. h2x +2For further technical planning, you can use the RapidAir Flow Rate Calculator to check specific pipe material capacities or consult The Engineering ToolBox for detailed pressure drop charts.

John you really need to get with the program if you're going to use AI...

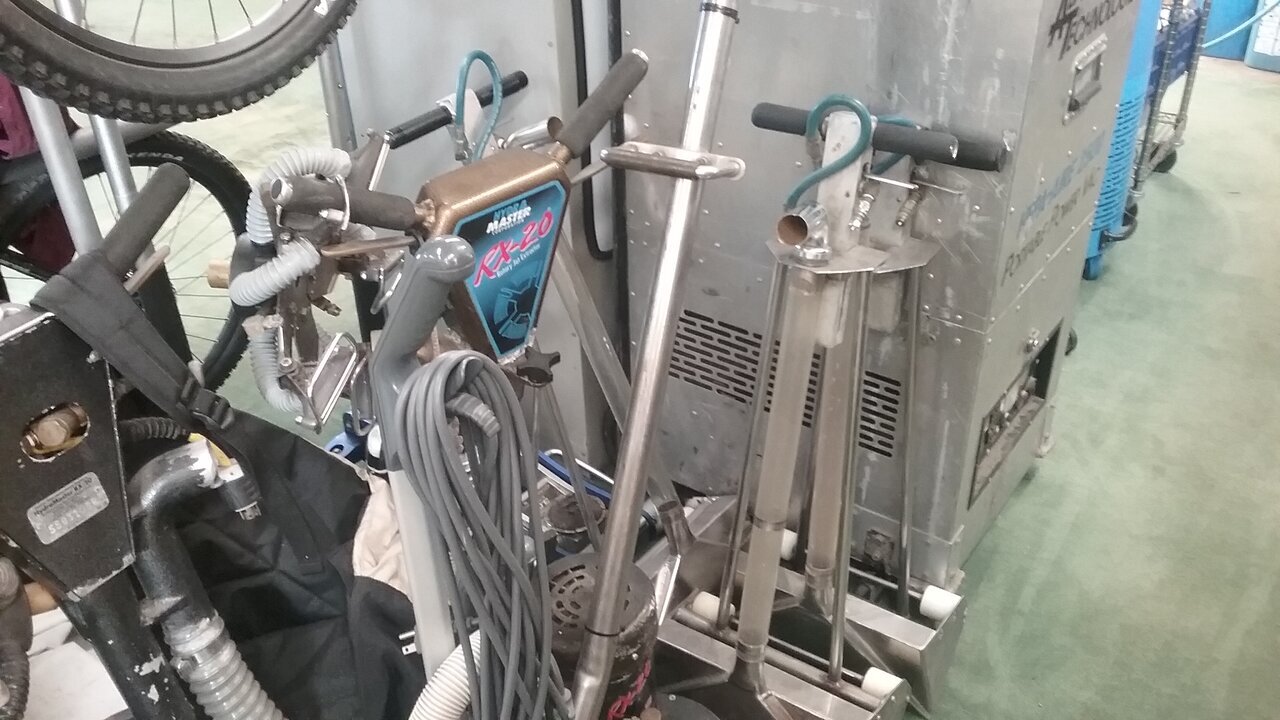

Let me show you how it's done

Since you’ve spent decades behind the wand, you know that the "disastrous" part of a 2-inch wand isn't the airflow—it's the ergonomics. Pushing a heavy, wide-bore wand for 8 hours a day takes a physical toll that a 1.5-inch wand with a whip hose simply doesn't.

However, once we add a Teflon

glide with 4 mm holes, the physics of the "choked" 1.5-inch system change. The glide becomes the primary regulator of the system, essentially leveling the playing field between the two diameters.

1. The "Orifice" Equalizer

In a wide-open wand, the hose diameter is the bottleneck. But when you add a hole-pattern glide, the total surface area of those 4 mm holes becomes the most restrictive point in the entire vacuum circuit.

If you have a 12-inch wand with 4 mm holes spaced across it, the cumulative area of those holes is likely less than the cross-sectional area of even a 1.5-inch pipe.

* 1.5-inch pipe area: \approx 1.77\text{ sq in}

* 2-inch pipe area: \approx 3.14\text{ sq in}

* Total area of 4 mm holes: Often falls between 0.5 and 1.2 sq in depending on the count.

Because the air is "metered" through the tiny holes at the carpet interface, the blower sees the same restriction regardless of whether the pipe behind it is 1.5 or 2 inches. This explains why your dry times are nearly identical: the glide is the bottleneck, not the wand.

2. Velocity at the "Face" vs. the "Pipe"

Your theory on velocity is correct specifically at the point of contact.

* Small holes in a Teflon glide create extremely high-velocity "jets" of air.

* This high-speed air shears water off the fibers more effectively than a wide-open 2-inch gap would.

* By the time that air moves from the 4 mm hole into the 1.5-inch wand, it has already done the "heavy lifting" of extraction.

3. The "Scrubbing" Factor and CFM

The reason the 2-inch wand is often touted is for Total CFM, but total CFM only matters if you can get it to the carpet.

* A 2-inch wand without a glide often "locks" to the carpet. When it locks, CFM drops to near zero, and you're just using static lift.

* Your 1.5-inch wand with a glide and whip hose never locks. It maintains a constant, high-velocity stream of air through those 4 mm holes. This constant airflow (even at a lower total volume) is more consistent at carrying moisture away than a 2-inch wand that is constantly sticking and stalling.

4. The Real-World Trade-off: Efficiency vs. Ergonomics

You are proving a point that lab tests often miss: The Human Variable.

* The 2-inch Wand: Theoretically moves more air, but causes faster operator fatigue and "locks" to the floor, requiring more physical force.

* The 1.5-inch + Whip: Moves enough air to clear the moisture provided by the glide, but allows for a faster, more fluid stroke.

Mathematical Summary: If the total area of your 4 mm holes is 1.0\text{ sq in}, then both a 1.5-inch (1.77\text{ sq in}) and a 2-inch (3.14\text{ sq in}) wand are "oversized" for the intake. The air will move through the wand at a lower velocity than it does through the holes, but since the 1.5-inch wand is closer in size to the "metered" intake of the glide, it maintains a higher internal velocity, which helps keep water droplets suspended in the air stream (preventing "fallout" in the hose).

The Verdict: You aren't seeing a "disaster" in dry times because the glide is doing the work of regulating the air. In this specific configuration, the 2-inch wand is overkill, providing no meaningful gain in extraction while significantly increasing the physical strain on your body.

Although that is a bit of an exaggeration, but I do try to move them minimally by emphasizing body movement over arm movement. So I don't become a deformed elderly carpet cleaning in years to come